baseball warm up routine pdf

Baseball Warm-Up Routine: A Comprehensive Guide

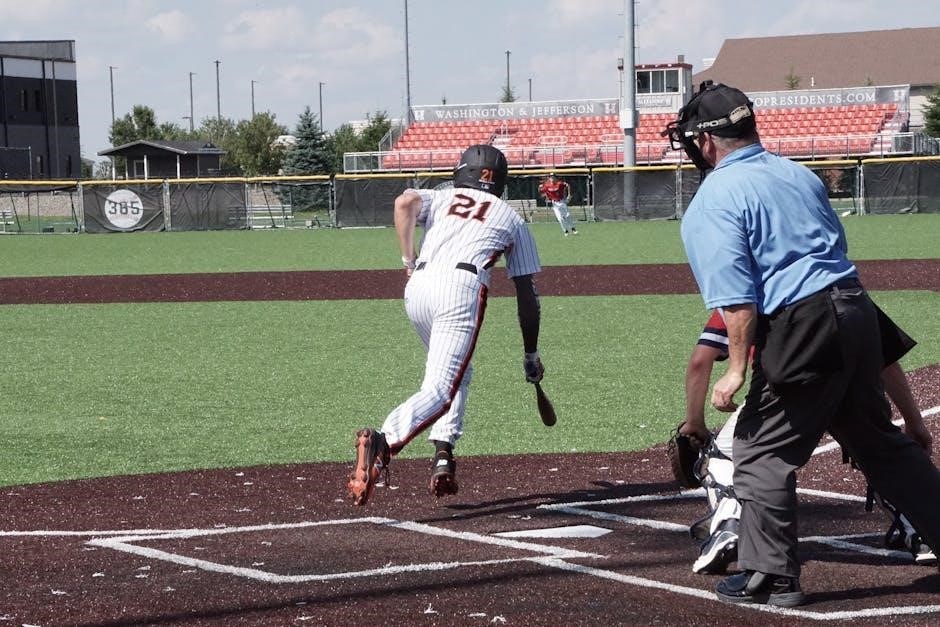

A well-structured baseball warm-up is crucial for injury prevention and optimal performance, encompassing dynamic movements and flexibility exercises tailored for the sport’s demands.

Understanding the Importance of a Baseball Warm-Up

A comprehensive warm-up is paramount in baseball, extending beyond simply preventing injuries; it actively enhances athletic performance. Preparing muscles for the specific demands of throwing, hitting, and fielding increases range of motion, improves neuromuscular efficiency, and elevates core body temperature.

Dynamic warm-ups, focusing on motion, are particularly beneficial, as they mimic baseball actions, unlike static stretching which can temporarily reduce power. The “dynamic means force as related to motion” principle highlights this advantage.

Proper preparation reduces the risk of strains, sprains, and more serious injuries. A focused warm-up primes the body, ensuring muscles are pliable and responsive, allowing players to react quickly and powerfully. Ignoring this crucial step can lead to decreased performance and increased susceptibility to setbacks, impacting both individual contribution and team success.

Dynamic vs. Static Stretching for Baseball

The debate between dynamic and static stretching for baseball centers on timing and impact on performance. Dynamic stretching, involving controlled movements through a full range of motion – like leg swings and torso twists – is ideal before activity; It prepares muscles for action, increasing blood flow and flexibility with movement.

Conversely, static stretching – holding a stretch for a prolonged period – is generally more effective after activity, during cool-down. While improving flexibility, static stretching before baseball can temporarily decrease muscle power and reaction time.

The principle of “flexibility is the ability to use joints fully” is best achieved through a combination, prioritizing dynamic movements pre-game and static stretches post-game. A dynamic warm-up phase, including running drills and mobility exercises, is specifically designed for baseball’s unique demands.

Warm-Up Duration and Timing

A comprehensive baseball warm-up should ideally span 20-30 minutes, strategically divided into phases to progressively prepare the body. Starting with a general warm-up (5-10 minutes) of light cardio, like jogging, increases blood flow. This is followed by 10-15 minutes of dynamic stretching, focusing on baseball-specific movements.

The final phase, baseball-specific drills (15-20 minutes), includes throwing progression, soft toss hitting, and fielding practice. Timing is crucial; begin the warm-up at least 20 minutes before game time or intensive practice.

A practice plan might allocate 20 minutes for warm-up, followed by hitting drills, position breakdown, and baserunning. Remember, a proper warm-up isn’t just about physical preparation; it’s about mentally focusing for optimal performance.

Equipment Needed for an Effective Warm-Up

While a robust baseball warm-up doesn’t demand extensive equipment, a few key items enhance its effectiveness. Primarily, a supply of baseballs is essential for throwing progression and fielding drills. A batting tee and soft toss net are invaluable for hitting practice, especially when cage access is limited.

Consider incorporating weighted or “heavy” baseballs to build arm strength and improve bat speed. Cones or markers can delineate running drills and agility exercises. A first-aid kit should always be readily available for minor injuries.

Depending on the drills, you might also need gloves, bats, and potentially a coach’s box for organized practice. Prioritizing safety and utilizing appropriate tools ensures a productive and injury-preventative warm-up session.

Phase 1: General Warm-Up (5-10 Minutes)

Begin with light cardio like jogging to elevate heart rate, followed by dynamic movements such as arm circles and shoulder rotations for increased mobility.

Light Cardio & Jogging

Initiating the warm-up with light cardio is paramount for preparing the cardiovascular system and muscles for more intense activity. A gentle jog, lasting approximately 5 minutes, gradually increases blood flow to the muscles, raising their temperature and enhancing elasticity. This reduced muscle stiffness minimizes the risk of strains and injuries.

Begin with a slow jog, focusing on maintaining good form and controlled breathing. Incorporate variations like side shuffling and backward jogging to engage different muscle groups and improve agility. These movements prepare the body for the specific demands of baseball, such as quick sprints and lateral movements.

The goal isn’t to exhaust yourself, but to gently elevate your heart rate and increase circulation. This phase primes the body for the subsequent dynamic stretching and baseball-specific drills, ensuring optimal performance and injury prevention. Remember to listen to your body and adjust the intensity as needed.

Arm Circles & Shoulder Rotations

Following the initial cardio, focus on mobilizing the shoulder joint with arm circles and rotations – critical for baseball players due to the repetitive overhead motions. Begin with small arm circles, gradually increasing the diameter to enhance range of motion and warm up the rotator cuff muscles. Perform both forward and backward circles, ensuring controlled movements.

Next, incorporate shoulder rotations, both internal and external, to further prepare the shoulder complex. These rotations improve flexibility and stability, reducing the risk of shoulder impingement or rotator cuff injuries; Focus on smooth, deliberate movements, avoiding any jerky or forced motions.

This phase is vital for preparing the throwing arm for the demands of throwing progression. Proper shoulder mobility and stability are essential for generating power and maintaining accuracy while minimizing the risk of injury. Aim for 30-60 seconds of each exercise.

Phase 2: Dynamic Stretching (10-15 Minutes)

Dynamic stretching prepares muscles for baseball-specific movements, improving flexibility and range of motion through controlled, active exercises, unlike static holds.

Leg Swings (Forward, Backward, and Lateral)

Leg swings are a foundational dynamic stretch, vital for increasing hip mobility and preparing the legs for the demands of running, fielding, and hitting in baseball. Begin with forward leg swings, gently swinging one leg forward and backward, focusing on controlled movement and increasing range of motion with each swing. Perform 10-15 swings per leg.

Next, incorporate backward leg swings, mirroring the forward motion but swinging the leg backward. This targets different muscle groups and further enhances hip flexibility. Again, aim for 10-15 swings per leg. Finally, add lateral leg swings, swinging the leg across the body and then outward. This improves adductor and abductor muscle activation, crucial for lateral movements on the field; Complete 10-15 swings per leg.

Maintain a stable core throughout all variations, and avoid overextending or forcing the swing. These movements should be fluid and controlled, preparing the muscles for more intense activity.

Torso Twists & Trunk Rotations

Torso twists and trunk rotations are essential dynamic stretches for baseball players, enhancing rotational power and flexibility – key components for hitting and throwing. Start with gentle torso twists, keeping your feet planted and core engaged. Rotate your upper body from side to side, allowing your arms to swing loosely. Perform 15-20 repetitions, focusing on controlled movement and avoiding jerky motions.

Progress to trunk rotations, which involve a slightly wider stance and a more deliberate twisting motion. Imagine rotating around your spine, engaging your obliques and core muscles. Complete 15-20 repetitions on each side. These exercises improve spinal mobility and prepare the core for the rotational forces experienced during gameplay.

Maintain a slight bend in your knees and keep your back straight throughout the exercise. Proper form is crucial to prevent injury and maximize effectiveness.

Walking Lunges with a Twist

Walking lunges with a twist are a dynamic stretch that combines lower body strength with upper body mobility, crucial for baseball’s rotational movements. Begin by stepping forward into a lunge position, ensuring your front knee doesn’t extend past your toes. As you lunge, twist your torso towards the front leg, keeping your core engaged and back straight.

Hold the twisted position briefly, then return to the starting position and repeat on the other side. Perform 10-12 repetitions per leg, focusing on controlled movements and a full range of motion. This exercise enhances hip flexibility, strengthens leg muscles, and improves rotational power.

Maintain a stable core throughout the exercise to prevent lower back strain. The twist should originate from the torso, not the hips.

High Knees & Butt Kicks

High knees and butt kicks are essential dynamic stretches for activating leg muscles and improving hip mobility, preparing players for explosive movements on the field. For high knees, jog in place while bringing your knees up towards your chest, aiming for a 90-degree angle. Focus on quick, controlled movements and maintain an upright posture.

For butt kicks, jog in place while bringing your heels up towards your glutes. Keep your thighs engaged and your core tight. Perform each exercise for 20-30 seconds, followed by a short rest. These drills increase blood flow to the legs, enhance coordination, and improve running mechanics.

Proper form is crucial to avoid injury; maintain a controlled pace and avoid overextending your joints.

Phase 3: Baseball-Specific Drills (15-20 Minutes)

This phase bridges the gap between general warm-up and game-like intensity, incorporating throwing, hitting, and fielding drills for baseball readiness.

Throwing Progression (Short Toss to Long Toss)

Initiate the throwing progression with short, controlled tosses – approximately 30-40 feet – focusing on proper mechanics and a relaxed arm action. Gradually increase the distance with each set of throws, progressing to medium throws (60-80 feet) and ultimately long toss (90-120 feet or more, depending on arm strength).

Emphasize a smooth, fluid motion throughout, prioritizing accuracy over velocity initially. This methodical approach incrementally prepares the arm for the demands of game-like throwing. Focus on maintaining good posture and utilizing the legs for power generation.

Avoid forceful, maximal-effort throws during the warm-up; the goal is to increase blood flow and activate the throwing muscles, not to fatigue them. Pay attention to any discomfort or pain, and adjust the intensity accordingly. Consider incorporating relay throws to simulate game situations and enhance throwing accuracy. This progression is vital for injury prevention and maximizing throwing performance.

Soft Toss Hitting Drills

Soft toss hitting drills are an excellent way to refine swing mechanics and hand-eye coordination during a baseball warm-up. Begin with the hitter focusing on making solid contact and driving the ball up the middle. The tosser should deliver soft, consistent tosses from a short distance, emphasizing a comfortable hitting plane.

Progress to drills that focus on specific aspects of the swing, such as top-hand or bottom-hand dominance, encouraging hitters to feel the correct mechanics. Utilize a net or designated area for safe and efficient practice.

Variations include tee work alongside soft toss, providing a stable platform for consistent contact. Heavy ball soft toss can also be incorporated to build bat speed and strength. These drills should be performed with controlled swings, prioritizing technique over power, preparing hitters for live pitching and enhancing their overall offensive performance.

Groundball Work (Infield & Outfield)

Groundball work is a vital component of a baseball warm-up, preparing infielders and outfielders for the demands of fielding batted balls. Infielders should focus on “around the world” groundballs, emphasizing proper footwork, glove presentation, and quick transitions. This drill builds agility and reaction time.

Outfielders should practice attacking groundballs, charging the ball aggressively and securing clean pickups. Relay throws are also crucial, working on accurate and efficient throws to bases. Short hops drills enhance fielding skills and hand-eye coordination for both positions.

These drills should simulate game-like scenarios, increasing intensity gradually. Proper technique and communication are key, fostering confidence and readiness for defensive plays. Focus on consistent repetitions and a proactive approach to fielding, ensuring players are prepared to make quick and accurate plays.

Short Hops & Fielding Practice

Short hops and focused fielding practice are essential for developing quick reactions and soft hands, crucial for infield and outfield players alike. This phase of the warm-up emphasizes controlled movements and precise technique.

Players should begin with easy rollers, gradually increasing the speed and difficulty of the throws. Focus on maintaining a low center of gravity, presenting a soft target with the glove, and securing the ball cleanly. Emphasize quick transitions from fielding to throwing, simulating game-like scenarios.

Drills should incorporate both forehand and backhand positions, challenging players’ versatility. Consistent repetition builds muscle memory and improves fielding confidence. Coaches should provide constructive feedback, correcting any mechanical flaws and reinforcing proper technique. This focused practice prepares players for the unpredictable nature of batted balls.

Cool-Down & Static Stretching (5-10 Minutes)

A proper cool-down with static stretches helps reduce muscle soreness and improves flexibility, aiding recovery and preventing post-exercise stiffness after exertion.

Hamstring Stretches

Seated Hamstring Stretch: Begin by sitting on the ground with legs extended straight out in front of you. Reach towards your toes, keeping your back as straight as possible. Hold this stretch for 20-30 seconds, feeling the stretch in the back of your thighs. Avoid bouncing, and breathe deeply throughout the exercise.

Standing Hamstring Stretch: Place one leg slightly in front of the other, keeping both legs straight but not locked. Gently lean forward from the hips, maintaining a straight back, until you feel a stretch in the hamstring of the forward leg. Hold for 20-30 seconds and repeat on the other side.

Dynamic Hamstring Stretch (Leg Swings): While maintaining control, gently swing one leg forward and backward, increasing the range of motion with each swing. This dynamic stretch prepares the hamstrings for explosive movements. Perform 10-15 swings per leg. These stretches are vital for baseball players due to the running and explosive movements required.

Quadriceps Stretches

Standing Quadriceps Stretch: Hold onto a stable surface for balance; Grab your foot behind you and gently pull it towards your glutes, keeping your knees close together. Feel the stretch in the front of your thigh. Hold for 20-30 seconds on each leg, ensuring a straight back and engaged core. Avoid bouncing.

Lying Quadriceps Stretch: Lie on your side and bend your top leg, grabbing your foot and pulling it towards your glutes. Keep your hips stable and feel the stretch in the front of your thigh. Hold for 20-30 seconds and repeat on the other side.

Dynamic Quadriceps Stretch (Walking Quad Stretch): While walking, bring your heel towards your glutes, holding the stretch briefly with each step. This dynamic movement prepares the quads for the demands of running and fielding. Perform for 10-15 steps per leg; Quadriceps flexibility is crucial for baseball players.